Hot Peel or Cold Peel: Which film to choose?

The key to DTF printing success lies in choosing the right film. In this article, we will delve into the differences between hot peel and cold peel DTF film, analyzing their features, advantages, and applications in detail to help you make informed purchasing decisions for your printing needs.

What is DTF Film?

DTF, or Direct to Film, is a printing technique that allows the transfer of designs directly onto clothing. In this technique, DTF film plays a crucial role as the print carrier. Its main purpose is to transfer patterns and graphics onto clothing. The process using DTF film involves printing a design on it using appropriate DTF inks. The film is then coated with DTF powder, which, when melted, will be responsible for adhering the print to the fabric. The film is then transferred onto the fabric's surface, after which the print is heated using a heat press. Under the influence of heat and pressure, the ink, along with the adhesive, transfers from the film to the fabric, creating a durable and vibrant print.

Main Differences Between Hot Peel and Cold Peel DTF Film

The choice between hot peel and cold peel DTF film depends on various factors, such as the type of project, the material on which the print will be applied, or the efficiency of the printing process.

Below is a detailed analysis of the differences between these two types of films:

Adhesive Component:

- Hot Peel Film: The main component is wax.

- Cold Peel Film: The main component is silicone.

Transfer of Prints:

- Hot Peel Film: Ideal for transferring large, uniform patterns.

- Cold Peel Film: Excellent for transferring both large and more intricate, delicate patterns, small icons, and letters with many details.

Costs:

- Hot Peel Film: More expensive in production. The production process of hot peel film is more complex and requires stricter standards for applying the wax coating, making it more expensive than cold peel film.

- Cold Peel Film: Cheaper compared to hot peel film. The transfer layer is easier to apply to the film.

Application on Materials:

- Hot Peel Film: Suitable for virtually all types of fabrics.

- Cold Peel Film: Works well on all types of fabrics and on specialized materials such as canvas, tarpaulin, flannel (due to quick drying, using hot peel film on such materials can lead to wrinkles and potential damage to the fabrics).

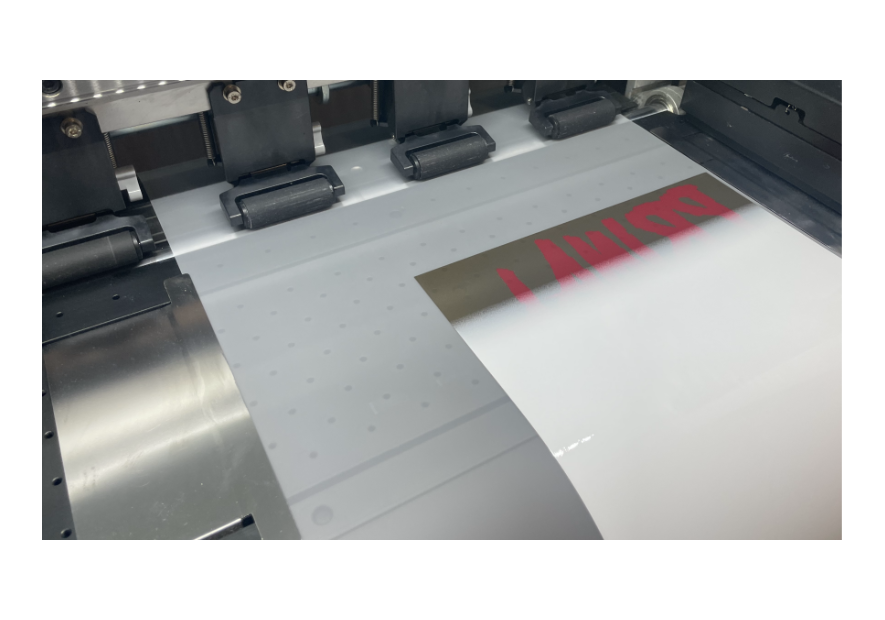

Efficiency:

- Hot Peel Film: Stands out in terms of efficiency, as it can be peeled almost immediately after pressing, allowing for fast production. With hot peel film, more than 100 shirts can be printed per hour.

- Cold Peel Film: Less efficient but offers excellent print quality.

Temperature and Heating Time:

- Hot Peel Film requires heating at a temperature between 140 and 150°C for 5-10 seconds, followed by cooling for 2-3 seconds. If not peeled off in time, the cooled film will adhere to the clothing, causing difficulties in tearing between the clothing and the film. The adhered adhesive layer of the film can result in material damage.

- Cold Peel Film requires a slightly higher pressing temperature (150-170°C) for 10-20 seconds and about 30 seconds of cooling before peeling off the film.

Color:

- Some users on foreign forums claim that the colors of prints on cold peel film look better, but from our test, there is no noticeable difference in color.

Conclusion

In conclusion, both hot peel and cold peel films have their unique features that make them suitable for different printing needs. When it comes to printing a large quantity on popular fabrics such as cotton shirts, hot peel film is ideal. On the other hand, cold peel film is excellent for printing intricate patterns or transferring prints to special materials.

In the next post, we will take a closer look at DTF film variants, Double Matte and Single Matte, analyzing their features, advantages, and areas of application to help you choose the right film for your projects.